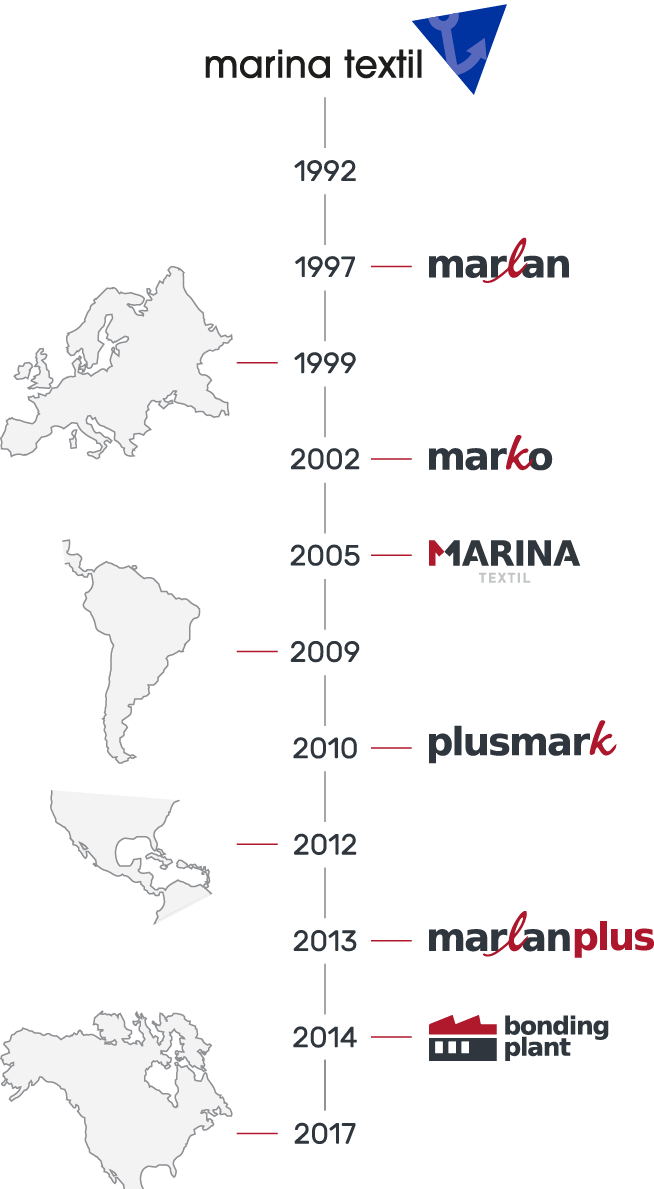

In 1992, Joan proposed that I join a business project in which we would design, manufacture, and sell fashion fabrics. This is how Marina Textil was born. We began our journey with a few looms, working for other local companies and offering our weaving services. In 1996, we launched our first fashion collection for men’s shirting.

In that same year, Marina Textil diversified its focus and began exploring the field of fire-resistant fabrics, also known as flame-retardant fabrics. One of our first launches was MARLAN, a flame-resistant fabric designed to protect against molten metal splashes. This product marked the beginning of our specialization in flame-retardant fabrics.

By 2007, 85% of our production was already focused on flame-retardant fabrics. This evolution not only reflected our adaptability to the market but also completely redesigned our business model and corporate strategy. Constant evolution has become a fundamental value at Marina Textil, as evidenced by the growth of our industrial capabilities, including the incorporation of a lamination plant and the systematic increase of our loom capacity.

Recently, Marina Textil has entered new sectors where flame-retardant fabrics are also used, such as fire protection, extreme temperatures, and racing drivers’ protective gear, through its subsidiaries Texfire and Marina Racewear.

The company’s evolution has led us to implement in-house laboratories focused on research and quality control. These laboratories allow us to test the resistance, durability, and flame-retardant properties of all fibers available on the market, as well as analyze all the fabrics we manufacture, ensuring quality compliance for each batch delivered to more than 70 countries worldwide.

With a constant focus on research and development, and a firm commitment to quality, rigor, and honesty in our relationships with customers and suppliers, Marina Textil remains dedicated to its mission of protecting people through the manufacture of technical fabrics with innovative fibers. The R&D team works in collaboration with universities and research centers to stay abreast of technological and material innovations, continuously improving and innovating our fabrics.

In line with our vision of sustainability, in 2020, we implemented a project that spans from the selection of eco-friendly raw materials to efficient and responsible production processes. We are committed to reducing our carbon footprint and promoting sustainable practices in all our operations and processes, ensuring a greener and more responsible future for the textile industry.

Today, at Marina Textil, we operate with a team of over 90 people, committed and passionate about their work. We are proud of our growth and the trust our customers place in our team, being recognized for our reliability and business philosophy. Thanks to our customers’ trust, we continue to work with the same enthusiasm and commitment as in our early days, ensuring the protection of those who wear garments made from our fabrics.

Thank you for your trust, we will continue to work as we have until now.

Raimon

General Manager of Marina Textil

OUR VALUES

RELIABILITY

Full commitment to service fulfilment and technical parameters of the product.

DEVELOPMENT

Design and execute strategies that contemplate a sustainable and positive future for the company.

SOLIDARITY

Actively help disadvantaged people with financial resources.

INTEGRITY

Seek personal and professional growth for the whole team through work.

We manufacture all of our fabrics at our facilities located in Barberá del Vallès. That is where the weaving machine depot and raw material and finished product warehouses, quality laboratory and new developments and research laboratory can be found, as well as the company commercial and administrative offices.

sustained growth

35% of our investments are in technical equipment for our own laboratories and research and innovation projects.

Companies from more than 50 countries already trust our technical fabrics.

Our annual average billing growth rate is 15%.

The volume of our stock allows us to ship more than 10,000 metres of fabric per day.

Our R+D+I department develops an average of 14 new projects per year.

Our current production capacity is around 3,000,000 metres per year.